Common Mistakes in Fulfillment Logistics and How to Avoid Them

Understanding the Importance of Fulfillment Logistics

In the fast-paced world of e-commerce, fulfillment logistics play a critical role in ensuring customer satisfaction and business success. However, many businesses encounter common pitfalls in their logistics processes that can lead to inefficiencies, increased costs, and unhappy customers. Understanding these mistakes and knowing how to avoid them is essential for optimizing your fulfillment operations and staying competitive in the market.

Overlooking Demand Forecasting

One of the most common mistakes in fulfillment logistics is failing to accurately forecast demand. Without proper demand forecasting, businesses risk either overstocking or understocking products. Overstocking ties up capital and warehouse space, while understocking leads to missed sales opportunities and dissatisfied customers.

To avoid this mistake, businesses should leverage data analytics tools to predict demand trends based on historical sales data, market trends, and seasonality. Regularly reviewing and updating these forecasts can help businesses align their inventory levels with actual demand, reducing waste and improving customer satisfaction.

Inefficient Warehouse Layout

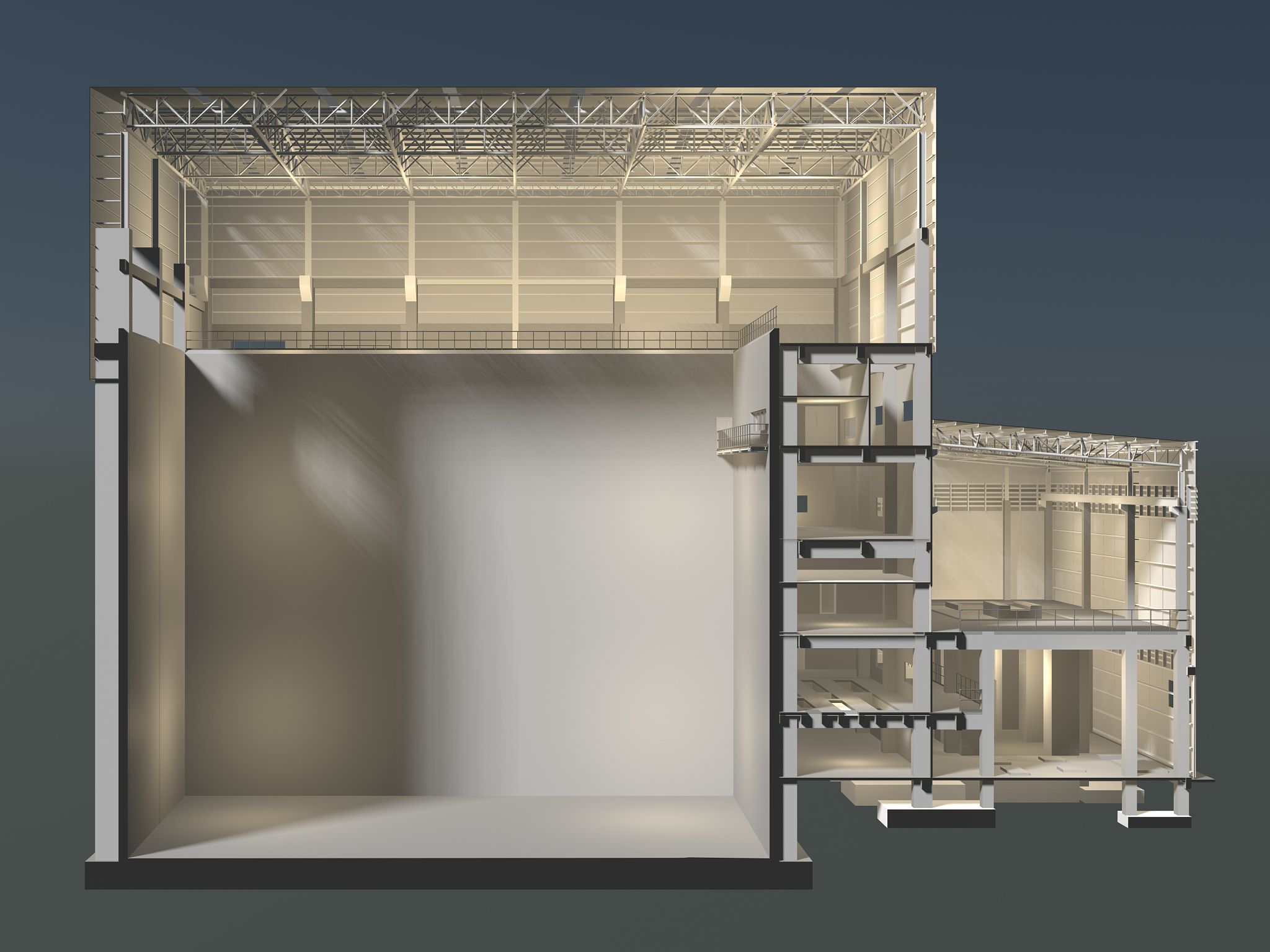

An inefficient warehouse layout can significantly hinder the speed and accuracy of order fulfillment. Poorly organized warehouses lead to longer picking times, increased errors, and delayed shipments. To optimize your warehouse layout, consider implementing a systematic approach by grouping high-demand items together and placing them closer to packing stations.

Incorporating technology such as barcode scanners and automated sorting systems can also streamline operations and reduce manual errors. Regularly reviewing and tweaking your warehouse layout can ensure it remains efficient as your business grows and evolves.

Lack of Inventory Visibility

Inventory visibility is crucial for maintaining efficient fulfillment logistics. Without real-time insights into inventory levels, businesses struggle to manage stock effectively, leading to stockouts or excess inventory. This lack of visibility can also result in poor decision-making regarding promotions and restocking.

Implementing an inventory management system that provides real-time tracking and reporting can dramatically improve inventory visibility. With accurate data at their fingertips, businesses can make informed decisions about purchasing, stocking, and selling products, ultimately enhancing their operational efficiency.

Poor Communication with Suppliers

Effective communication with suppliers is key to avoiding disruptions in the supply chain. Poor communication can lead to delays in receiving goods, incorrect orders, and strained relationships with suppliers. To prevent these issues, establish clear communication channels and maintain regular contact with your suppliers.

Consider using technology platforms that facilitate seamless communication and collaboration with suppliers, enabling quick responses to changes in demand or supply chain disruptions. Building strong relationships with suppliers can also foster mutual trust and reliability in your fulfillment logistics process.

Ignoring Customer Feedback

Lastly, ignoring customer feedback is a critical mistake that can hinder the improvement of fulfillment logistics. Customer feedback provides valuable insights into your fulfillment process from the consumer's perspective. Ignoring this feedback can result in missed opportunities for improvement and persistent customer dissatisfaction.

Actively seeking and analyzing customer feedback regarding delivery times, packaging quality, and overall service can help identify areas for enhancement. Implementing changes based on this feedback demonstrates a commitment to customer satisfaction and can lead to improved customer loyalty.

Conclusion

Avoiding common mistakes in fulfillment logistics requires attention to detail, effective use of technology, and a proactive approach to problem-solving. By addressing issues such as demand forecasting, warehouse layout, inventory visibility, supplier communication, and customer feedback, businesses can streamline their operations and provide a better experience for their customers. Staying vigilant and adaptable in these areas will not only improve efficiency but also bolster the overall success of your logistics strategy.